We Are Climate Label Certified

In October of 2023 we officially became Climate Label Certified by The Change Climate Project. The process of becoming Climate Label Certified was a months-long effort to measure, reduce, and compensate for our carbon footprint. Our carbon footprint is the amount of climate warming gasses that are the result of any activities associated with our chocolate company. This includes everything from the vehicles used to transport cacao beans from farms, to fermentaries and then across the ocean to our factory, to the paper cups we use at our Krog Street Market shop to serve drinking chocolate.

While the certification process took several months, the journey was much longer…

Elaine and Matt’s son looking out over rainforest on a cacao farm in Nicaragua.

Our Beginnings

Our concern about sustainability, the environment, and climate change long predates the founding of Xocolatl Chocolate. So when we created Xocolatl we knew we wanted to create something more than a chocolate company. The goal was to build a business that lived up to our values. Building an environmentally sustainable business has been a priority from day one.

So, what does that mean? Where do you start?

Measure

From the very beginning we worked to source sustainably grown cacao, sugar, and other ingredients, as well as packaging and supplies (not always successfully), and we did other things like recycling, using an electric car for deliveries, and giving cacao husks leftover from our chocolate making to gardeners and farmers, but we knew this wasn’t nearly enough.

We knew we needed to measure our impact on the environment. So that’s what we did.

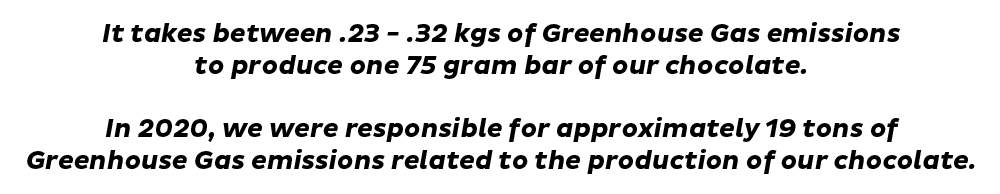

In 2021, we commissioned a friend (and former Xocolatl Chocolate Maker) who was completing a graduate program at Georgia Tech to do a Life Cycle Analysis (LCA) of our chocolate bars. An LCA measures the amount of Greenhouse Gas emissions (GHG) that are released in the process of making a bar of our chocolate—and we included everything. We gathered information from farmers (on three different continents) on the vehicles they use to transport beans to the fermentary, from the mill that makes the paper for our wrappers (good news, they’re 100% recycled paper made in a factory powered by 100% renewable energy), from our own power bills, and dozens of other inputs to calculate the total emissions related to making a bar of chocolate.

The result?

Action

- The first thing we realized was that the vast majority (over 80%) of our emissions come from the electricity we consume at our shop and factory in Atlanta. Fortunately, before we even got the results of our LCA, we signed up for a program with our power company to purchase Renewable Energy Credits (RECs) for 100% of the power we consume at our shop and new factory. RECs work as if we are using renewable energy. Power companies produce a certain amount of renewable energy every year. While they can’t send that energy directly to our factory, we can pay a premium for our portion of the total they produce. The more the demand for renewables increases the more the power companies will produce. Most states have similar programs, but if you’re in Georgia you can do the same for your home or business and sign up here.

The Renewable Energy Credit summary from our February 2023 factory power bill.

- In 2022, we purchased 25 tons of carbon credits protecting rainforest and an orangutan habitat in Indonesia. In 2023, we purchased 25 tons of carbon credits protecting rainforest in Brazil, and an additional 100 tons of carbon credits protecting one of the planet’s largest remaining peat swamp forests in Indonesia. We have concerns about the efficacy of carbon credits, but we think Pachama is working to raise carbon credit standards through their use of hi-tech data monitoring systems. However, because of our concerns about carbon credits, since 2023 we’ve redirected our investments towards lowering our own carbon footprint, most notably through updating our packaging material as described below.

- We pay to literally suck carbon dioxide out of the air. We use Climeworks, a Swiss company that built a facility in Iceland that extracts carbon dioxide out of the air and stores it deep underground where it mineralizes to stone permanently. This is way more expensive than carbon credits (85-100 times more expensive), but we’re going to have to do more than protect existing rainforests to save our climate. As of September 2025 our monthly subscription paid to suck over over 3,500 kgs of CO² every year. You can read more about this amazing company and set up your own monthly subscription here.

Climeworks plant in Iceland that sucks CO² out of the air, trapping it underground.

- We use an app that calculates the CO² emissions related to shipping our online orders to customers and purchase carbon credits and carbon capture to offset the CO² released during transit. Since 2022, we’ve offset emissions related to shipments that have cumulatively traveled more than 3,000,000 miles.

- In the past, we donated cacao husks to local gardeners and farmers, but the reality was we were still throwing a lot of cacao husks (and other potentially compostable items) in the trash. Starting in 2022, we set up a composting service first with Compost Now, and more recently with a local non-profit, The Life Cooperative. Since then we’ve composted nearly 13,000 pounds of cacao husks, food waste, and paper products. That’s the equivalent of eliminating nearly 15 tons of GHG emissions.

Our Impact Report from Compost Now. That’s a lot of tomatoes!

- Through Greenspark we purchase 10kgs of carbon credits for every single order on our online store (that’s in addition to the credits we purchase to offset mileage seen in #4!). These credits support a variety of projects from hydroelectric energy in Chile to helping to transition families from traditional three-stone cooking fires to much more efficient wood burning stoves in Malawi (where Elaine was a Peace Corps volunteer!). We’ve purchased over 60 tons of credits through Greenspark since 2022.

- In 2024, we achieved a longtime goal of moving our products packaged in plastic pouches (cacao nibs, trail mix, etc) into fully home compostable pouches. The new, fully compostable pouches cost over 600% more than our old plastic pouches, but we believe this is the type of investment we all need to make to transition to a sustainable economy.

- We were first Carbon Neutral Certified by ClimateNeutral.orgin 2022. Since then ClimateNeutral has changed their name to the Change Climate Project and their certification is now called The Climate Label. This change was made in large part because of the same concerns we had over carbon offsets and the reality that no company can truly claim to be carbon neutral today. However, we continue to be certified under their new Climate Label every year in an effort to maintain transparency and accountability of our efforts to continue to reduce our footprint. The Change Climate Project sets the industry standard for climate accountability and we’re proud to carry the Climate Label. You can check out our annual reports here

No Finish Line

This is a long journey and there is no finish line, but we’re going to keep building a chocolate company that makes as small an impact on the environment as possible and one that brings joy to your day.

With love for you and our planet,

Elaine, Matt, and the whole Xocolatl team